Here is my second post, some refections as the busy trade show season is mostly over.

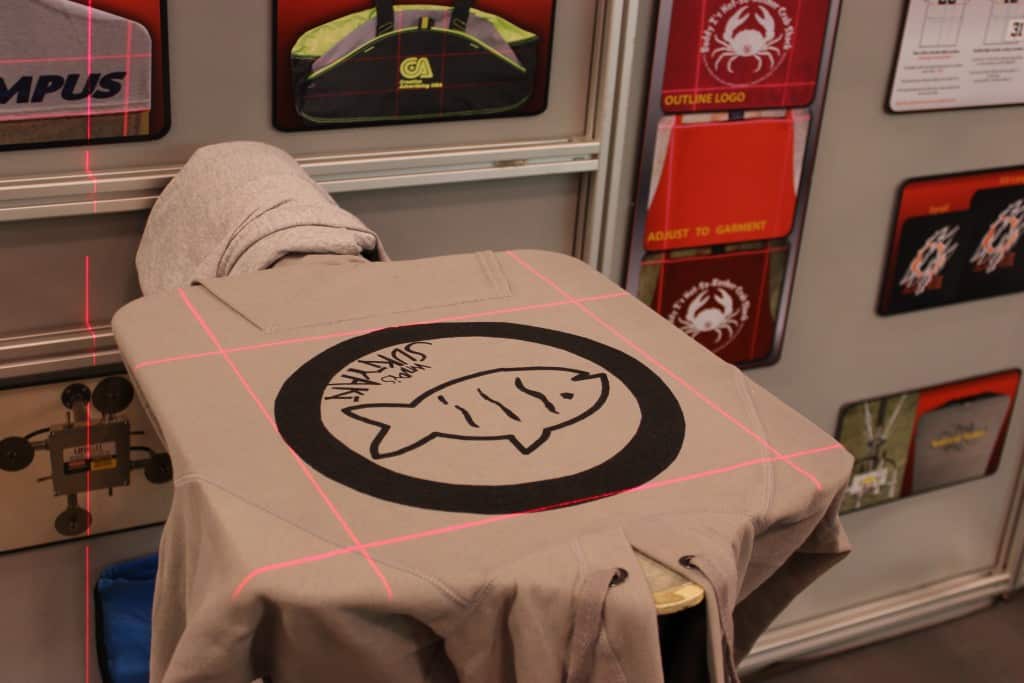

The biggest trends of the past ten years have been related to digital printing and to concerns about the effects of printing and garments on the environment. Developments in the environmental realm seem to have slowed down, but still do continue and I assure you they will not stop. We have to find increasingly safe and sustainable ways to do our work. Digital printing continues to innovate and to grow.

The next round of developments in our industry are going to be in the area of systems. You may be able to print one shirt at a time quickly, however you will eventually find a bottleneck not in the time it takes to print, but rather in the time it takes to transfer information. What print, what garment, and where is it going? How are those payments going to be processed? The rise of companies like Jakprints that process thousands of orders accurately is the future and the future is here now. Much of that happens on the back end, which is not a particularly photogenic area, so I don’t have many photos in what follows.

With that commentary, I’ll now get into what I do have photos of. Thanks to Ashley Marie Myers and Pam Ikegami who took quite a few of these photos.

Comments