I would rather be writing about the Mothers of Invention, Frank Zappa and all that, than thinking about nylon.

We always avoided printing on nylon, but eventually we somewhat embraced it. Nylon shrinks when you heat it and ink doesn’t really want to adhere to it and nobody technical gives you any consistent information, other than that it is great stuff to work with.

This tale is starts with a big problem, gets silly and ultimately has a very happy ending.

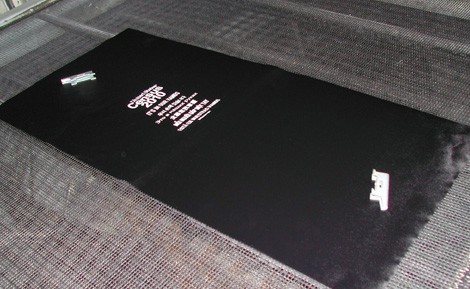

Big problem to start. We print simple print on black 200 denier nylon. (Denier is a measure of thickness/weight/fiber strength that I don’t entirely understand.) Pretty thin nylon is a fair description of the piece in question. We are told that the vendor can only accept one quarter inch of shrinkage over the length of the piece, which is not much. We then played experimentation games with the dryer and the amount of catalyst until we get the ink to mostly cure and the fabric to mostly not shrink.

Great, ready to roll… except the light canvas blows around in the oven and ink gets all over the pieces. grrrrrr. No problem, I go out back and saw up a million small blocks of wood (sticks) to hold the ends down.

This is a pain for the person unloading, but seems to work. However, upon closer examination it causes a problem. There is a slight mark where the wood lies. The wood doesn’t seem to be that hot or anything. Aha, actually it shields the nylon and basically the whole panel is shrinking very slightly, but under the wood it shrinks not at all and it causes a slight pucker.

So we searched for something smaller and went from sticks to stones. Literally we went out and found them in the parking lot. They were heavy enough to hold the nylon down but didn’t have a big footprint on the nylon, but they still had a little mark left on the nylon after passing through the oven.

We started looking around for what else we could weight down the nylon with and found some light metal brackets, but they left small dimples as well.

Finally, necessity is the mother of invention and somebody tried what I thought was not a good idea and folded the nylon in half and then looped the second end over as well. I thought that the blowing air in the oven would catch the openings and make things worth. However, I was wrong and I think the static holds the two loose ends in place. Whatever the reason, it worked and we printed thousands of panels and they didn’t blow around any longer. We not only didn’t ruin any more panels, we didn’t cause any more marks whatsoever on the fabric, and it was faster than putting sticks or stones on the ends. Home run.

Comments