Discharge is an ugly sounding process.

Of course most discharge inks are kind of an ugly business.

However, that is another story.

The basics of discharge are that instead of covering up the darkness of a shirt with a couple of coats of ink, the discharge ink “neutralizes” the dye in the shirt. It isn’ t bleaching, but it seems something like that. It is a water-based ink and has a soft hand after printing. Mostly it is used to get a soft feel on a soft fabric.

However, there are some other reasons to use discharge.

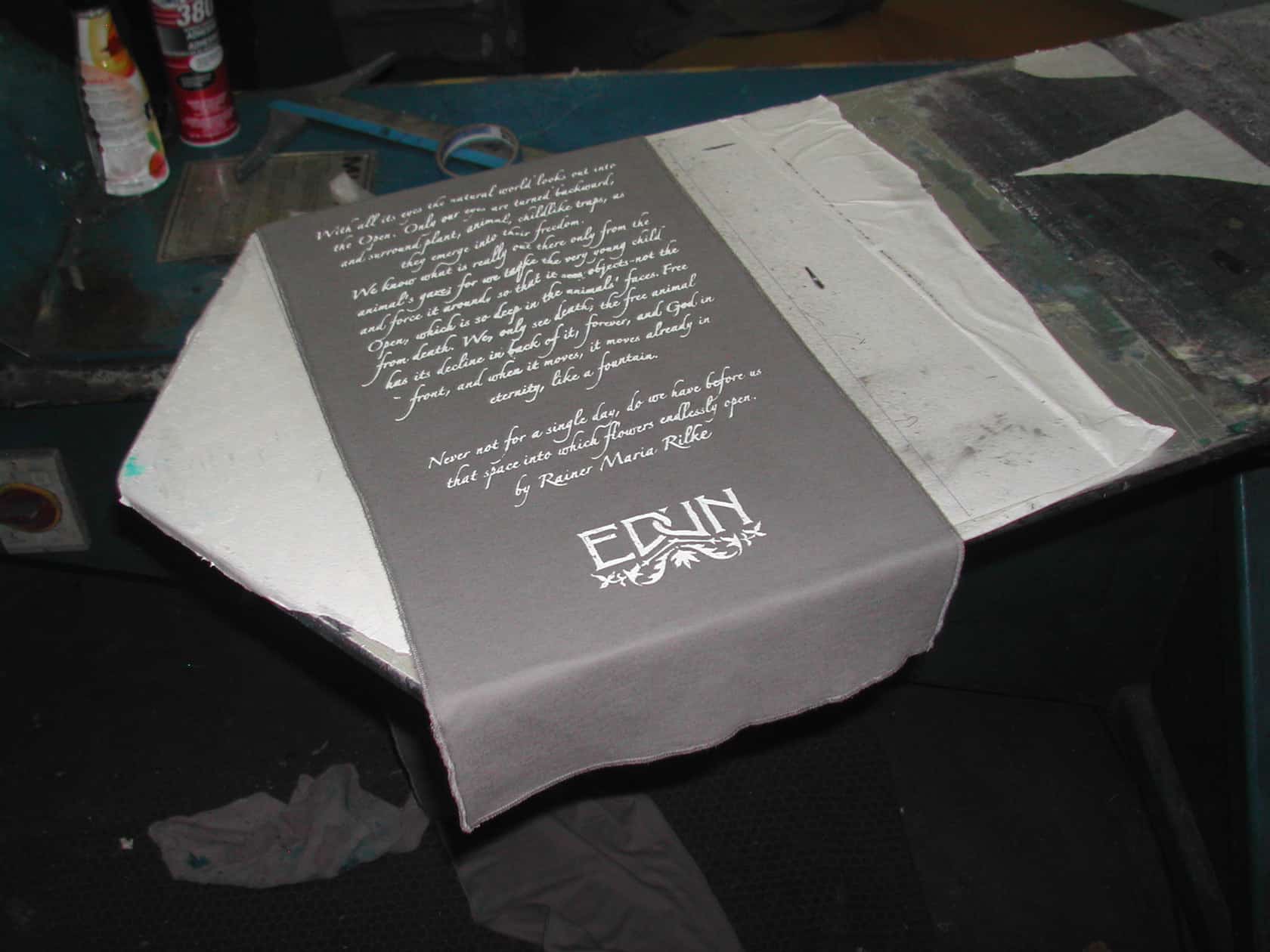

We used to print a job today for the fair trade company Edun. This is a scarf which was pretty popular for Edun, partly because U2’s singer Bono wore one at the Obama inauguration festivities.

These are dark colored scarves and normally with plastisol inks you might print an underwhite and an overwhite and be done with it.

However, these scarves are two-ply. They have two layers and the problem is that if you printed an underwhite and went to print an overwhite then the scarf might move and it would go out of register and ultimately make a mess.

Usually in printing you lightly tack (glue) down the shirt, scarf or whatever fabric and print it as many times as you want and it stays in place. However, in this instance you would be only gluing the bottom layer and the top would move and the words on the scarf would get blurry and we can’ t have that.

Discharge ink allows for one pass and so solves this problem.

Comments