Why Can’t I Hold Detail in My Screenprints?

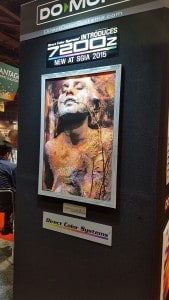

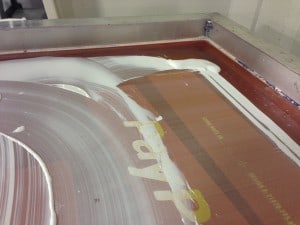

This question comes up often with screenprinters: why can we not hold detail? The answer is an idea similar to the art department concept of problems with source artwork where we say “garbage in, garbage out.” We are now are transferring that idea to print production. Basically, if you have a crappy stencil you have no chance…