All purpose ink that works for everything? Fahgettaboudit

Today’s post considers a new dye blocking ink to print with a little more smooth, soft, and stretchy results.

These days if you only want to print basic t-shirts you will go out of business. Polyesters, spandex, bamboo, rayon, triblends, wicking, ringspun, open end and all kinds of new things all the time are finding their way into the garments we see in our shops. To get the kind of results that folks want to see whether retail, team, organization, or promotional now requires you to have a full complement of inks to help you get through each and every situation you encounter.

We printed a nice fashionable top, a garment containing “elastica” which is a fabric we were not familiar with. This garment was from American Apparel and they are pretty good about giving direction to decorate their garments, but many manufacturers are not and you just have to protect yourself, particularly in regards to dye migration (the dye of the shirt going into the ink, sometimes taking weeks to do it.)

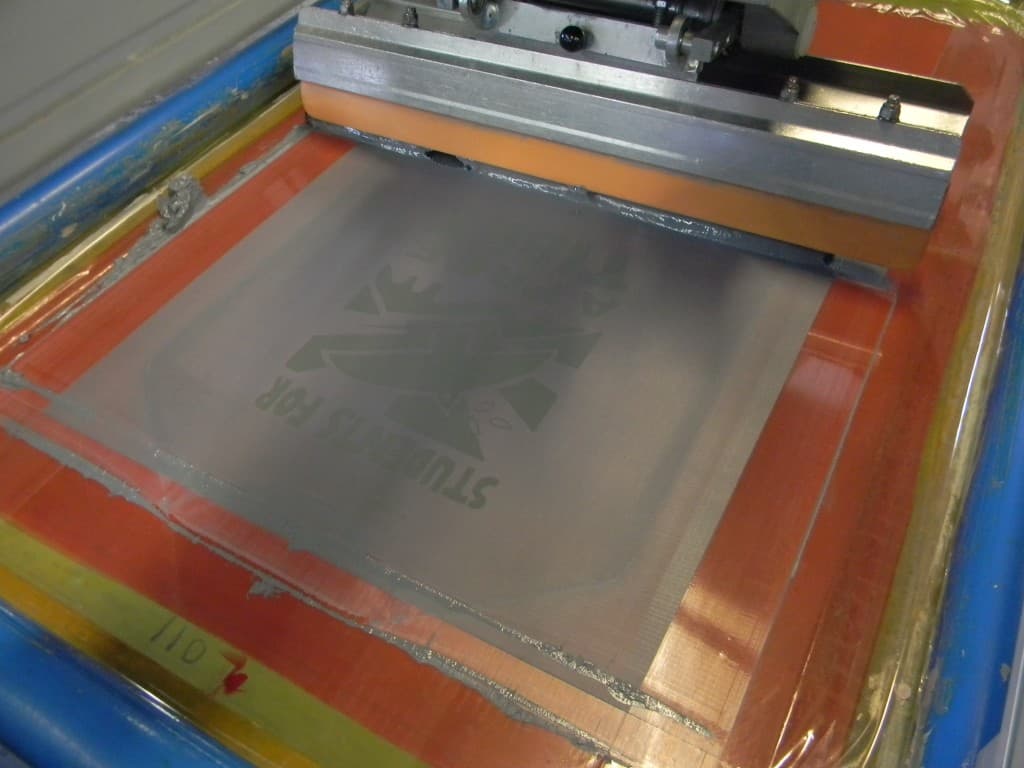

So this new ink (Endurance Plus) from Rutland is a polyester ink. We often use their regular barrier grey as the best tool we have to prevent dye migration, but it can be a little tough to use and you can’t really add any reducers to it to make it print easier. It also does not cure to be particularly soft and it is not particularly able to stretch. The new Endurance Plus poly ink both in the grey dye block and white give us a tool to stop all but the worst dye migration while giving a smoother softer print and also giving us extreme stretchability.

Comments